Reduce Loss and Errors Using UHF RFID Warehouse Inventory Tags

By hqt

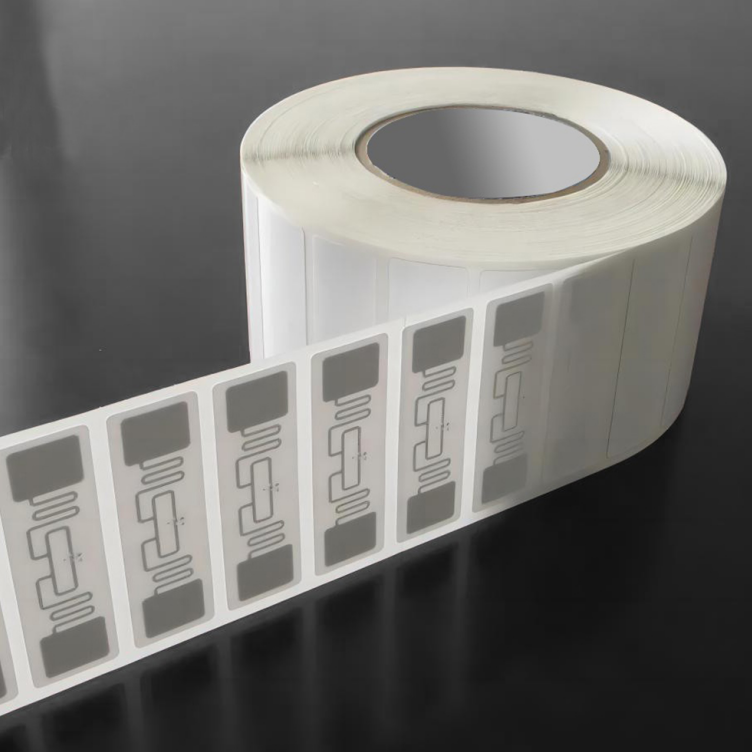

A UHF RFID Warehouse Inventory Tag is a small, durable label embedded with an RFID chip that uses ultra-high frequency (UHF) radio waves to track inventory. It enables fast, accurate, and automated scanning of items over long distances, improving efficiency and reducing errors in warehouse management.With traditional methods often leading to delays and mistakes, these advanced tags provide a smart solution for businesses looking to streamline operations. But how exactly do they work, and why should your warehouse make the switch? Keep reading to discover how UHF RFID Warehouse Inventory Tags can transform your inventory management.

The Challenges Warehouse Managers Face

Warehouse managers have long struggled with various challenges that compromise inventory accuracy and operational efficiency. These include manual processes, outdated tracking methods, and the difficulty of handling large volumes of stock. Common issues in inventory management are:

- Manual Scanning Inefficiencies: Traditional methods of inventory tracking often involve labor-intensive manual scanning, which is not only time-consuming but also prone to human error. These errors can lead to incorrect stock counts, missing items, and delays in order fulfillment.

- Rising Labor Costs: As the volume of inventory increases, the need for additional staff to manually track and manage stock also rises, contributing to higher labor costs. This puts pressure on businesses to optimize their operations without sacrificing quality or service.

- Stock Loss and Theft: Without a precise and automated tracking system, inventory discrepancies often go unnoticed. Lost or misplaced items can remain undetected for long periods, leading to financial losses and operational disruptions.

- Lack of Real-Time Visibility: Many warehouses still rely on outdated tracking systems that do not offer real-time inventory updates. This lack of visibility can result in delays, overstocking, or stockouts, which ultimately impact order fulfillment and customer satisfaction.

These common pain points in inventory management not only reduce efficiency but also significantly increase costs and operational risks. Fortunately, UHF RFID Warehouse Inventory Tags offer an innovative solution to address these issues effectively.

How UHF RFID Warehouse Inventory Tags Revolutionize Operations

The introduction of UHF RFID Warehouse Inventory Tags has transformed inventory management, offering features that improve accuracy, speed, and efficiency in tracking stock. These tags are designed to meet the challenges of modern warehouses, making inventory control simpler and more reliable. Some of the key features and benefits include:

- Speed and Precision: One of the standout advantages of UHF RFID tags is their ability to scan large quantities of items in just a few seconds. Unlike manual scanning, which is slow and prone to errors, RFID technology can scan up to 200 items in one second. This is more than 20 times faster than traditional methods, helping warehouses keep up with the demands of high-volume inventory operations.

- Long-Distance Reading: UHF RFID tags have a flexible reading range, allowing them to be scanned from distances between 3 to 15 meters. This feature is particularly beneficial for warehouses with high-speed operations involving forklifts, conveyors, or automated machinery. The ability to read tags without precise alignment makes UHF RFID tags ideal for large-scale facilities.

- Durability for Harsh Environments: Designed for durability, UHF RFID tags can withstand tough conditions, including exposure to metal surfaces and water. With an IP68 rating, these tags are waterproof and can endure extreme temperatures ranging from -40°C to 85°C, making them suitable for outdoor warehouses, automotive manufacturing, and other challenging environments.

- Unique Identification and Data Storage: Each RFID tag is equipped with a unique 96-bit EPC code that ensures every item is traceable. In addition to basic identification, UHF RFID tags can store additional data, such as production dates, batch numbers, and maintenance records. This enhances the accuracy of inventory tracking and provides valuable insights for supply chain management.

- Improving Inventory Accuracy and Reducing Errors

The benefits of UHF RFID Warehouse Inventory Tags extend beyond just speed and durability; they also significantly reduce errors and increase the accuracy of stock management. With RFID tags, warehouses can enjoy:

- Real-Time Inventory Tracking: Automated scanning allows for continuous inventory updates, minimizing human error and ensuring that stock levels are always accurate. This provides better visibility into stock availability, preventing overstocking or stockouts.

- Faster Inventory Turnover: UHF RFID technology accelerates the inventory process, reducing the time it takes to process and move stock. This is particularly important for just-in-time inventory systems that rely on speed and efficiency to meet customer demands.

- Minimized Stock Loss and Shrinkage: By eliminating manual data entry and enhancing tracking capabilities, RFID technology helps prevent stock loss and theft. The ability to track items in real-time ensures that any discrepancies can be identified and resolved quickly, protecting both inventory and revenue.

Why Crystal Code‘s UHF RFID Warehouse Inventory Tags Are the Best Choice

At Crystal Code, we are committed to providing businesses with the most reliable and effective UHF RFID solutions. Our UHF RFID Warehouse Inventory Tags are designed with the following features to meet the needs of modern warehouses:

- Versatile Materials: We offer a range of materials for our UHF RFID tags, including paper, PET, ABS, epoxy, and PC, allowing you to choose the best option for your specific environment and requirements. Whether you need a flexible or durable solution, our tags are adaptable to various applications.

- Global Compatibility: Our RFID tags are compliant with international standards such as CE, FCC, IC, RoHS, and REACH. This ensures that our tags are suitable for use across various regions and industries, offering global compatibility and reliable performance.

- Customizable Options: We provide flexibility in memory configurations, offering 96-bit or 128-bit EPC memory, with user memory options ranging from 32-bit to 8 KB. This customization allows businesses to store critical data and integrate RFID tags into their existing systems seamlessly.

By choosing Crystal Code’s UHF RFID Warehouse Inventory Tags, businesses can improve operational efficiency, enhance inventory accuracy, and reduce costly errors. Whether you are managing a small warehouse or a large distribution center, our RFID tags provide the reliability and performance needed to stay ahead of the competition.

Take Control of Your Inventory Today

Don’t let inefficiencies and errors hinder your warehouse operations. Contact Crystal Code today to learn more about how our UHF RFID Warehouse Inventory Tags can help you optimize inventory management, reduce loss, and increase accuracy. Our expert team is here to help you implement RFID technology that will transform the way you manage your stock. Visit our website or reach out to us for more information on how we can assist you in improving your warehouse operations with our cutting-edge RFID solutions.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper