From Heat to Highway: The Tyre Sticker That Survives 210°C and Beyond

By hqt

In the world of tyre manufacturing, few materials face more intense conditions than a tyre vulcanization sticker. Exposed to extreme heat, pressure, and chemical reactions, these small labels must perform under stress that would destroy ordinary materials. Imagine surviving 210°C – or more – without losing shape, color, or adhesion. That’s not just durability; it’s innovation.

But how does a simple sticker withstand such punishment? What materials, processes, or technologies lie behind its strength? And most importantly, why does it matter to the future of tyres on the road?

In this article, we’ll peel back the layers – literally and figuratively – to reveal the science, the challenges, and the breakthrough that made it all possible.

Introduction: A Sticker That Defies Fire

The Hidden Challenge in Tyre Production

Tyre production isn’t just about rubber and steel. It’s also about labels – small components that carry big responsibilities. These labels must survive extreme environments, including heat, pressure, and chemical exposure. Most stickers simply can’t take the heat. They melt, fall off, or become unreadable during the vulcanization process.

Why Ordinary Labels Don‘t Work

Traditional labels are not made for high temperatures. During vulcanization, they lose adhesion, discolor, or distort. They can’t hold up to 210°C, let alone remain legible after it. In such a harsh setting, failure isn’t rare – it’s expected.

The Rise of the Tyre Vulcanization Sticker

The tyre vulcanization sticker was developed to solve this problem. Built with advanced materials, it resists heat, pressure, and chemical exposure. Even after facing temperatures up to 210°C, the label stays secure and the barcode stays readable.

Introducing Crystal Code

At Crystal Code, we design labels for industrial challenges. Our tyre vulcanization sticker is made to endure the most intense conditions in tyre manufacturing. It’s more than a label – it’s a part of the tyre itself.

The Vulcanization Gauntlet: Inside The Tyre-Making Furnace

What Is Tyre Vulcanization?

Vulcanization is the core of tyre production. It strengthens the rubber by exposing it to heat and pressure. This transforms raw rubber into a tough, flexible, and durable material suitable for the road.

A Harsh Environment for Labels

During vulcanization, tyres are exposed to heat levels between 130°C and 210°C. The process also includes intense pressure and chemical reactions. These conditions are too extreme for normal adhesives and label materials.

A Label That Stays Strong

A tyre vulcanization sticker must do more than stick. It needs to integrate with the tyre. It must resist temperature shifts, oil, water, abrasion, and even solvents. Only a specialized label can take on this role – and last through the entire life of the tyre.

The Hero Of High Heat: Crystal Code‘s Vulcanization Sticker

What Sets Our Sticker Apart

Our tyre vulcanization sticker is made to withstand the same heat, pressure, and chemicals the tyre does. It doesn’t crack, peel, or fade. It bonds during vulcanization and stays firmly attached – no matter what conditions the tyre faces later.

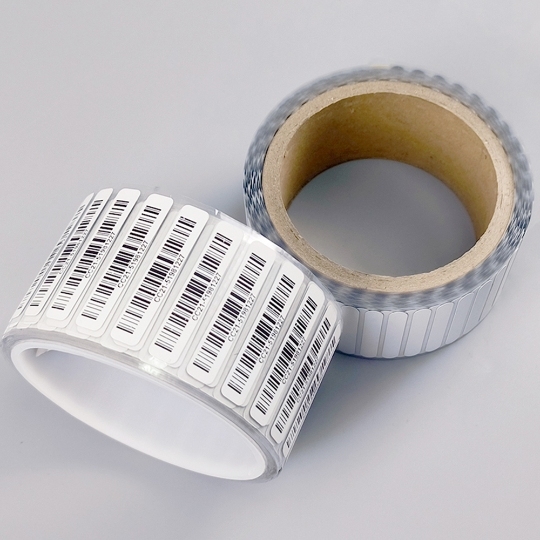

Key Features at a Glance

- Material: White polyester with a high-durability topcoat

- Adhesive: Rubber bonding formula designed for vulcanization

- Sizes: 44×8mm, 38×8mm, or customized on request

- Temperature Resistance: 130°C to 210°C

- Printing Compatibility: Works with most carbon resin ribbons

- Storage Life: Up to 3 years at standard room conditions

Integrated With the Tyre

Our sticker doesn’t just sit on the surface. It becomes part of the tyre during vulcanization. Once bonded, it remains fixed throughout the tyre’s lifecycle. The printed barcode stays clear, scannable, and resistant to wear.

Built for the Long Road

Whether exposed to rain, oil, road salt, or mechanical abrasion, our sticker performs without fail. It resists chemicals, solvents, and temperature extremes. This makes it ideal for global supply chains and long-haul use.

Crystal Code‘s Promise

We know tyre manufacturers demand consistency and durability. That’s why we built this sticker to meet the highest industrial standards. With Crystal Code, you get a tyre vulcanization sticker that delivers performance from factory to freeway.

Unshakable Adhesion: Sticking Through The Lifecycle

Bonding Strength: Built To Stay Put

The tyre vulcanization sticker is engineered to bond deeply with the tyre surface. It does not peel off, warp, or detach, even under the pressure of vulcanization. The rubber-based adhesive forms a strong connection during the heat process. Once applied, it stays where it belongs – from the factory to the highway.

Lifecycle Performance: Start To Finish

This sticker performs throughout the full life of the tyre. It begins at the production line, goes through vulcanization, then continues through warehousing, distribution, and road use. Even after thousands of kilometers, the label remains intact and readable. It handles tough driving conditions, wet environments, and regular wear.

Surface Versatility: Made For All Tyre Types

Our tyre vulcanization sticker works with many tyre surfaces. Whether it’s for passenger cars, trucks, or industrial tyres, the label adapts well. It bonds to smooth or textured rubber, giving manufacturers full flexibility.

Clear, Crisp, And Durable: Print Quality Under Pressure

Resin Ribbon Compatibility: High-Quality Prints

Our sticker works with most carbon resin ribbons. It delivers sharp barcodes and clean text, even under heat. Printing is smooth, and the result is resistant to fading and smearing. The combination of quality material and resin ribbon ensures each print is long-lasting.

Barcode And Text Legibility: Always Readable

Readability is critical. The tyre vulcanization sticker keeps barcodes and serial numbers clear and scannable. Even after exposure to high temperatures, oil, or friction, the printed information remains intact. This supports tracking, logistics, and inventory management.

Industrial Use Case: Reliable In Real-Time Scanning

In manufacturing lines and warehouses, time matters. Our label can be scanned quickly and accurately. It performs well under fast-paced conditions, helping teams manage tyre batches, shipments, and stock. The data stays reliable at every stage.

Material Science In Motion: Engineered For Resistance

Composition & Protection: Multi-Layered Defense

The material used in our tyre vulcanization sticker includes a high-strength polyester base and a heat-resistant topcoat. It protects against moisture, oil, salt, and industrial chemicals. Whether the tyre is in storage, on the road, or exposed to rough weather, the label holds up.

Abrasion And Solvent Resistance: Made For Rough Handling

Tyres are often moved, stacked, and transported in bulk. This brings friction and contact with other surfaces. Our sticker resists scratches, scrapes, and rubbing. It also holds strong against low-fat solvents, cleaning agents, and petroleum-based substances.

High/Low Temp Tolerance: Built For Global Transport

From freezing warehouses to scorching production floors, the sticker remains stable. It handles both high heat and low temperatures with ease. This makes it suitable for tyres shipped around the world, across all climate zones.

Why Crystal Code Leads The Label Race

Innovation Backed By Industry Know-How

At Crystal Code, we combine advanced materials with deep industry knowledge. We understand what tyre makers need – durability, readability, and reliability. Our tyre vulcanization sticker is the result of years of testing and real-world application.

Customization Options: Made To Fit Your Process

Not all tyres are the same, and not all labels should be either. We offer custom sizes, thicknesses, and formats. Whether you need a 44x8mm label or something specific, we can deliver. You can also choose adhesive strength and surface finishes that match your production needs.

Three-Year Shelf Life: Reliable When You Need It

Our stickers are made to last – even before they’re used. With a shelf life of up to three years at normal storage temperatures, you can stock them with confidence. They stay effective and ready for application when production scales up.

Start Your Journey with Reliable Tyre Identification Solutions

The tyre vulcanization sticker from Crystal Code delivers performance that lasts the entire life of a tyre. From extreme heat during production to harsh road conditions, it stays bonded, readable, and reliable. For manufacturers, suppliers, and logistics teams, this means fewer errors, better tracking, and stronger product integrity. At Crystal Code, we’re committed to creating durable, high-performance labels that meet the future of tyre manufacturing – head-on.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper