Why Many Brands Misuse Thermochromic Labels – and How to Fix It

By hqt

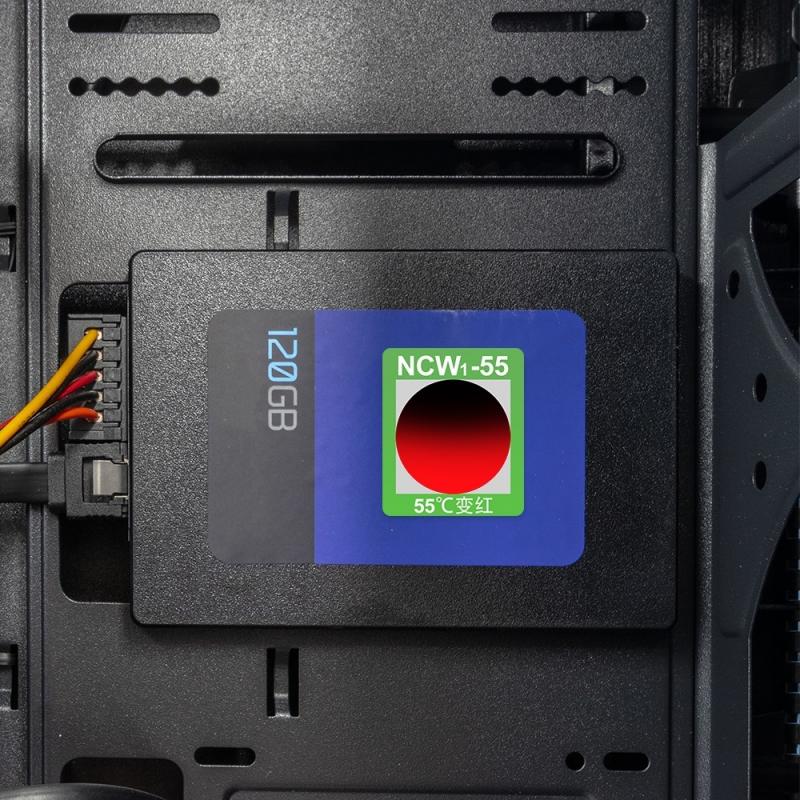

Thermochromic Labels change color when temperature shifts. They offer a fast, visual cue without tools. What are they? Heat-sensitive labels that react to cold and heat, then switch back when conditions normalize. Where do they work? Cold-chain food, vaccines and pharma, lab samples, electronics, and machinery safety checks. Teams use them on cartons, vials, and panels to spot risk at a glance. So why do they fail in real life – causing spoiled goods and audit pain? The answer is not the chemistry. It’s the setup. Let’s uncover the fix.

Where Thermochromic Labels Go Wrong

Most misuse starts before a label touches a box. Brands pick a label, not a temperature strategy. They treat Thermochromic Labels like stickers, not sensing tools. The result is data you cannot trust and actions you cannot take.

Wrong trigger ranges. Teams select indicators that shift at the wrong points for the product. A dairy pack needs a narrow cold window; an electronics enclosure needs a broader, safer band. If the window is off by even a few degrees, the color tells the wrong story.

Reversible vs. irreversible confusion. Some need to know if a spike happened at any time; others need continuous, real-time monitoring while conditions change. Many buyers want real-time but purchase irreversible dots. That drives false alarms or missed ones.

Poor placement. A label over foam or air gaps lags behind the actual product temperature. A label on a curved corner can peel and let condensation blur the reading. Placement is as important as choosing the chemistry.

Hard-to-read signals. Dull inks, low contrast, and small patches make a fast check slow. Operators guess. Guessing becomes variance. Variance becomes waste.

No operator training. Warehouse teams often get zero guidance beyond “turns red when warm.” Without a simple SOP – what to check, when to check, how to record – Thermochromic Labels become decoration.

Documentation holes. Auditors want a trail. Photos, timestamps, and lot links are missing. Temperature events are noticed but not logged.

✅ Quick checkpoint:

• Choose the correct temperature window for your product profile.

• Match reversible or irreversible to your use case.

• Place labels on stable, representative surfaces.

• Use clear, high-contrast visuals.

• Train staff and standardize logging.

How Crystal Code Fixes The Gap

At Crystal Code, we design Reversible Temperature Indicator Labels to answer these pain points with reliable, readable feedback – without extra tools.

- Accurate, Reversible Monitoring You Can Trust

Our Thermochromic Labels change color with both heat and cold, then switch back as conditions normalize. That means continuous visibility during storage, loading, transit, and receiving. You see the state now, not just a past spike. The fast response suits sensitive settings like pharmaceutical storage, refrigerated food, and machinery safety checks where minutes matter.

- Built For Real Work, Not Lab Shelves

We engineer for durability. The face material is matte with a special inkjet-receptive coating, giving sharp, high-contrast color changes and clean on-label printing. Typical face stock is about 70 g, backed by 80–140 g white or glassine liners for stable application. The adhesive grips plastics, metals, and packaging films, and stays readable even around condensation. Features include waterproof performance, good tack, easy cut and peel, and bright colors that stand out at a glance.

✅ Operator-friendly details:

• Easy to apply & read: clear color shift – no device required.

• Inkjet printable: add SKUs, batch codes, or handling notes on demand.

• Custom sizes: fit vials, cartons, totes, or panel tags.

• Certifications: SGS / RoHS / ISO to support quality reviews.

Where do they shine? Cold-chain food, vaccine and drug logistics, lab research, electronics protection, and industrial maintenance. In each case, Thermochromic Labels offer instant decisions: release, isolate, or re-cool.

What To Do Next: A Simple Deployment Playbook

A good label needs a good workflow. Here’s a straightforward rollout we use with new Crystal Code customers. It is short, clear, and works in the field.

Step 1: Map The Temperature Risks

List the points where your product can drift: loading docks, cross-docks, last-mile vans, warehouse aisles, equipment housings. For each point pick the safe range and how long exposure matters. This gives you the trigger windows for your Thermochromic Labels.

Step 2: Choose Reversible Indicators For Live Control

If your team needs ongoing visibility, use reversible indicators. You can see if the product is safe right now and re-assess after corrective action. Add printed fields via inkjet – SKU, lot, and time – to link events to inventory.

• Pro tip: Pair a reversible on the outside (fast screening) with a data logger on critical lanes (audit depth). You cut cost while keeping proof.

Step 3: Place, Train, and Pilot

Place labels on flat, representative surfaces near the product mass, not over voids. Write a one-page SOP with photos: where to stick, what “OK” looks like, what “Act” looks like, and how to record. Run a two-week pilot on a few lanes and adjust placement or window if signals feel too sensitive or too dull.

✅ Pilot success signals:

• Fewer “not sure” readings from staff.

• Faster receiving checks at the dock.

• Clear go/no-go decisions during excursions.

Step 4: Lock In Documentation

Create a simple log: date, lot, zone, label state, action. Snap a photo when color changes. This ties Thermochromic Labels to your QA system and satisfies audits without extra devices.

Step 5: Scale And Optimize

Order custom sizes for your common packages. Use bright, consistent artwork for fast recognition. Review spoilage or rework rates monthly and tune the trigger windows if needed.

Final Words

Ready to stop temperature guesswork? Talk to Crystal Code about our Reversible Temperature Indicator Labels. We’ll help you choose the right Thermochromic Labels, set up a pilot, and train your team – so you cut waste, pass audits, and protect product quality.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper