High-Heat Temperature Indicator Labels for Extreme Conditions

By hqt

A temperature indicator label may look like any ordinary sticker, yet its fate is anything but ordinary. Every day in furnaces, curing ovens, and sterilizers, these small squares fight blistering air, whirling grit, and caustic splashes – keeping batch numbers and safety data clear when everything else bends or melts. This article unpacks why specialty labels matter, how we at Crystal Code build them, and where they quietly save the day in real-world factories.

Why Ordinary Labels Collapse

Most production managers learn the hard way that a standard paper label will singe, curl, and vanish long before equipment reaches its operating temperature. The fallout is painful:

✅ Lost Traceability – when a part emerges from a 400 °C paint line with no ID, re-testing or scrapping is the only safe option.

✅ Regulatory Trouble – food or pharma products without readable temperature records can’t legally ship.

✅ Downtime and Rework – operators spend hours hunting for paperwork or printing fresh tags instead of running the line.

What defeats common adhesives and inks?

• Constant radiant heat that browns paper fibers.

• Sudden spikes – think forge doors opening – that shock the substrate.

• Chemical baths or pickling acids that leach dye pigments.

A robust temperature indicator label therefore needs three essentials:

✅ Heat-stable film such as polyimide or stainless foil that refuses to deform up to 800 °C.

✅ Ink systems fused into the material, not merely sitting on top.

✅ Adhesives or mechanical fasteners matched to the surface energy of steel, glass, or alloy.

How We Build Heat-Proof Confidence

I’m often asked why we at Crystal Code obsess over tiny design tweaks that barely show to the eye. The answer is simple: when a label ends its life in a molten-metal scrap bin yet its barcode still scans, that’s product-market fit.

- Materials That Out-Work the Environment

Our CC-ST series spans four temperature tiers (250 °C, 400 °C, 600 °C, 800 °C) because a solder-reflow oven does not abuse a tag the way a steel annealer does. By layering polyimide with micro-thin aluminum or switching to 0.1 mm stainless, we give each temperature indicator label a thermal runway long enough for the whole process, not just the hottest moment.

- Print Chemistry That Refuses to Fade

Rather than laying ink in a neat film (easy to scratch), we embed pigments below the surface or sinter ceramic particles directly into the face stock. The print head runs slower, but the resulting text survives abrasives and acids that would strip normal dyes in seconds.

- Customization Without the Pain

Need a corporate color? Want a QR code plus Arabic and Thai batch text? We gang-run those variables through digital presses, then laser-kiss-cut the shape you like. Because tooling is virtual, a client can reorder with a single email – no plate fees, no waiting.

- Rapid Life-Cycle Testing

Every production lot hits a salt-spray chamber and a staged oven ramp. If a label emerges brittle or shows discoloration, we re-formulate before shipping. It is slower than drop-shipping generic tags, but it keeps your audit trail intact.

Real-World Wins

• Heavy Metal, Light Worries

A northern European steel mill once swapped our CC-ST-80 stainless labels for their traditional wire tags. After three months, they reported a reduction in tracking errors because barcodes stayed scannable from the slab caster to the finishing line – a path that peaks above 750 °C.

• Automotive Paint Shops

During e-coat and bake cycles, vehicles see 180 °C for 30 minutes. Our 400 °C range labels laugh at that heat. One client noted that warranty claims tied to paint defects dropped simply because parts were no longer mis-matched after baking – staff could trace each frame correctly through the booth.

• Food Retort Packaging

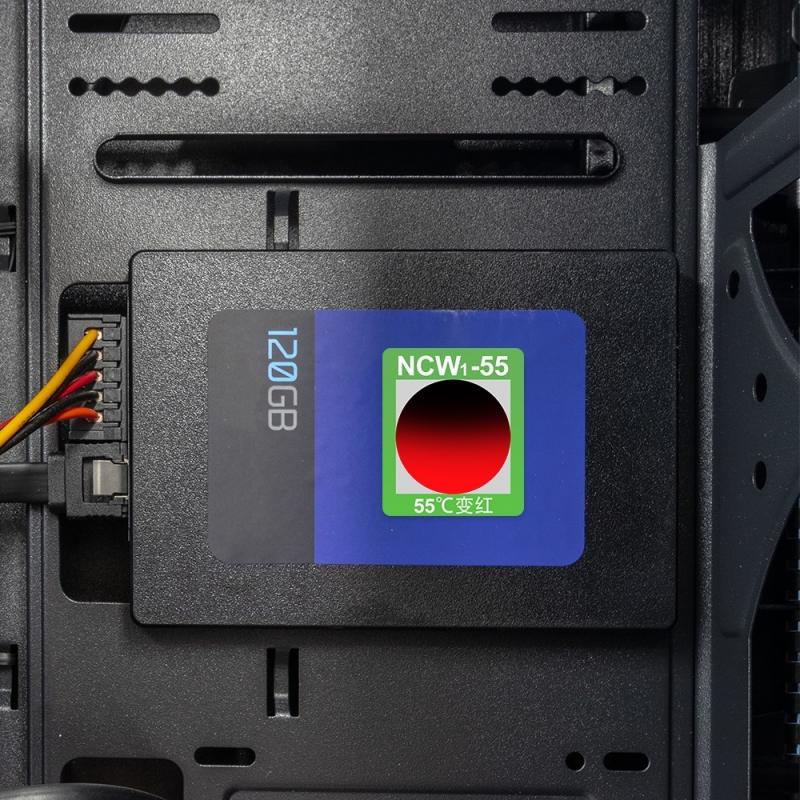

In canneries, retort cookers hit 121 °C steam for sterilization. While that temperature sounds tame, saturated moisture destroys cheap paper tags. Polyimide labels endure the steam, and their irreversible color-shift dot confirms every can experienced the full cook cycle – critical for shelf-life and safety.

• Electronics Reflow Lines

Printed circuit boards travel through multiple reflow passes near 260 °C. A temperature indicator label on the panel edge records thermal history and carries part IDs beyond final QA. Engineers scan labels to pull oven telemetry, spotting hotspots before they trigger latent solder fractures in the field.

Closing Thoughts

A temperature indicator label is not glamorous, but it is a silent insurance policy for any facility that lives in the red zone of the thermometer. It keeps safety inspectors calm, accountants happy, and production flowing. At Crystal Code, we treat each label like a mission-critical part, because for many of our customers, it is the only proof a product endured – or survived – the heat. Curious which construction fits your line? Drop us a test spec, and we’ll match a label that outlasts your toughest shift. In the meantime, check the tags already on your floor: if they look tired, it may be time for an upgrade that refuses to blink in the face of fire.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper