RFID Barcode Label vs Manual Scan: Solve Inventory Pain

By hqt

RFID Barcode Label is the fastest way for operations teams to eliminate counting delays, data errors, and line slowdowns that come with manual scanning. At Crystal Code, we work with warehouse, logistics, and manufacturing leaders who are under pressure to do more with less. Labor is tight, assets are moving faster, and customers expect real-time visibility. In this article, we compare manual scanning with our RFID approach and show how Crystal Code helps you close the gap between physical flow and digital truth.

Why Manual Scanning Creates Inventory Pain

Manual scanning was built for a slower world. It demands line-of-sight, precise alignment, and person-by-person diligence. As volumes rise, so do blind spots. Teams miss items on high shelves, pallets move before they’re recorded, and seasonal staff struggle with complex workflows. The result is the same in every industry: miscounts, cycle count drift, and reconciliation work that eats into margins.

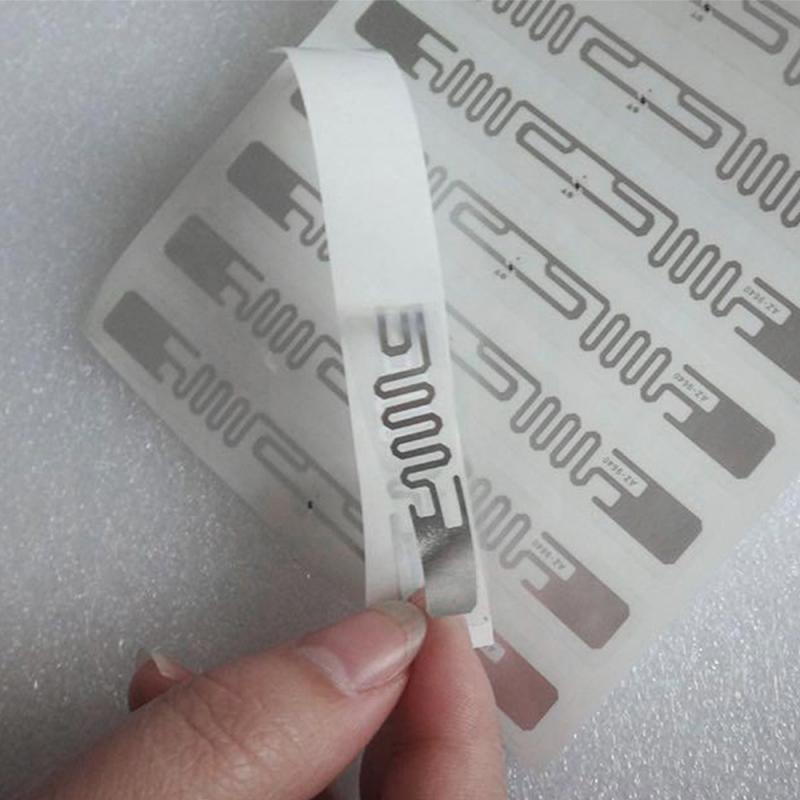

RFID changes the workflow. Instead of pointing a scanner at each barcode, you read many tags at once. With our RFID Barcode Label, near-field precision can scan over 200 items in 1 second (reader power dependent). That is more than 20x the efficiency of manual scanning, and it removes the stop-and-scan rhythm that slows pick, pack, and ship. For fast-moving environments, ultra-long-distance flexible reading enables dynamic recognition from 3 to 15 meters. Forklifts and conveyor belts keep moving; operators do not need perfect alignment. This is the core reason RFID inventory tracking in warehouses delivers measurable speed, accuracy, and labor relief.

How Crystal Code‘s RFID Barcode Label Solves It

At Crystal Code, we design each RFID Barcode Label to perform in the field, not just in a spec sheet. Below are the essentials that matter during rollout and everyday operations.

✅ Performance Specs At A Glance

• Read Speed: Up to 200 tags/sec (depending on reader power)

• Read Range: Passive 0.5-12 m; Active 30-100 m

• Frequency Range: 860-960 MHz (Global UHF)

• Protocol: EPC Class 1 Gen 2 (ISO/IEC 18000-63)

These figures support dense inventory zones, moving lines, and mixed asset types without micromanaging angles or distance.

✅ Built For Real-World Conditions

• Harsh Environments: Optional anti-metal and waterproof IP68 versions; resistance -40 °C to 85 °C for storage yards, outdoor use, and automotive manufacturing

• Materials: Paper / PET / ABS / Epoxy / PC to match durability and surface needs

• Attachment: Pressure-sensitive adhesive, rivets, or epoxy for stable, long-life mounting

• Metal Performance: Anti-metal models available (3-10 dB gain)

You can label racks, bins, returnable containers, tools, or vehicle components and keep consistent reads across varied conditions.

✅ Data, Standards, And Compliance

• Unique IDs: 96-bit EPC globally unique (128-bit options available)

• User Memory: 32-bit to 8 KB (optional) to store production dates, batch numbers, or maintenance records

• Rewrite Cycles: 100,000+

• IP Ratings: Paper IP54; Industrial IP67/IP68

• Global Approvals: CE, FCC, IC, RoHS, REACH

With an RFID Barcode Label, you get a durable digital identity plus extensible memory for traceability – ideal for audits, recalls, and after-sales service. It’s also easy to integrate: our labels conform to widely adopted UHF standards so your readers, middleware, and WMS/ERP can speak the same language. For organizations comparing RFID vs barcode scanning, these capabilities unlock automation without adding complexity.

Implementation Tips And ROI Proof

Transitioning from manual scanning is less about hardware and more about flow design. At Crystal Code, we recommend a phased approach that protects throughput while proving value fast.

Start with a constrained, high-pain process such as inbound receiving, cycle counts on high-value SKUs, or work-in-process tracking between stations. Use our bar-shaped ultra-high frequency RFID sticker label format for tight spaces and curved surfaces. In near-field applications, you gain rapid, precise reads; on lines or docks, 3-15 m dynamic recognition captures moving items without breaking pace. Because every tag carries a globally unique 96-bit EPC, reconciliation becomes straightforward. Extend your data model with user memory for production dates, batch numbers, and maintenance records – no extra database joins or handheld inputs required.

From an ROI view, the math is simple. Manual scanning ties up people, slows vehicles, and creates downstream corrections. With our RFID Barcode Label, you replace one-by-one scans with multi-item reads, cutting count time and exceptions. You also reduce write-off risk because labels are rewriteable 100,000+ times, and industrial builds withstand -40 °C to 85 °C and IP67/IP68 conditions. Over weeks, that yields cleaner inventory, fewer expedites, and smoother audits. Over months, it compresses cycle count windows and unlocks automation, from gate-in visibility to conveyor merges. For cross-border or regulated industries, CE, FCC, IC, RoHS, and REACH approvals simplify compliance reviews and purchasing.

Call To Action – See It In Your Flow

If manual scans are holding back your teams, let Crystal Code map a focused pilot around your highest-impact route or line. We’ll provide the right RFID Barcode Label construction (Paper, PET, ABS, Epoxy, or PC), attachment method, and memory plan, then validate read rates on your floor with your readers. Reach out to Crystal Code to schedule a quick discovery session and get a tailored bill of materials for your first success path.

When accuracy, speed, and durability matter, the choice is clear. Manual scanning was fine for yesterday’s cadence. Crystal Code’s RFID Barcode Label brings real-time visibility to today’s operations – so your system always matches reality, and your teams stay in flow.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper