How NFC Temperature Label Solves Cold Chain Monitoring Issues

By hqt

NFC Temperature Label is changing how cold chains tell the truth. Boxes no longer travel blind. A tap reveals identity, location, and live temperature. No spreadsheets. No guesswork. Spoilage and audits stop being a gamble. Yet most operations still miss the brief spikes that cause big losses. Where are those blind spots hiding? And how can a simple label expose them – without slowing the line? Read on to see how the weakest links appear, how data closes them, and why the fix is easier than you think.

The Visibility Gap In Cold Chains

Cold chains often fail in small, quiet ways. A pallet waits ten extra minutes on a sunny loading bay. A reefer door is propped open during a busy shift change. A sensor is installed but never read. Paper logs look complete, yet no one can prove a brief temperature excursion that happened at 03:14. These moments compound into spoilage, claims, and tense audits. Whether you manage food logistics or biologics and vaccines, the pattern is familiar: you can’t correct what you can’t verify.

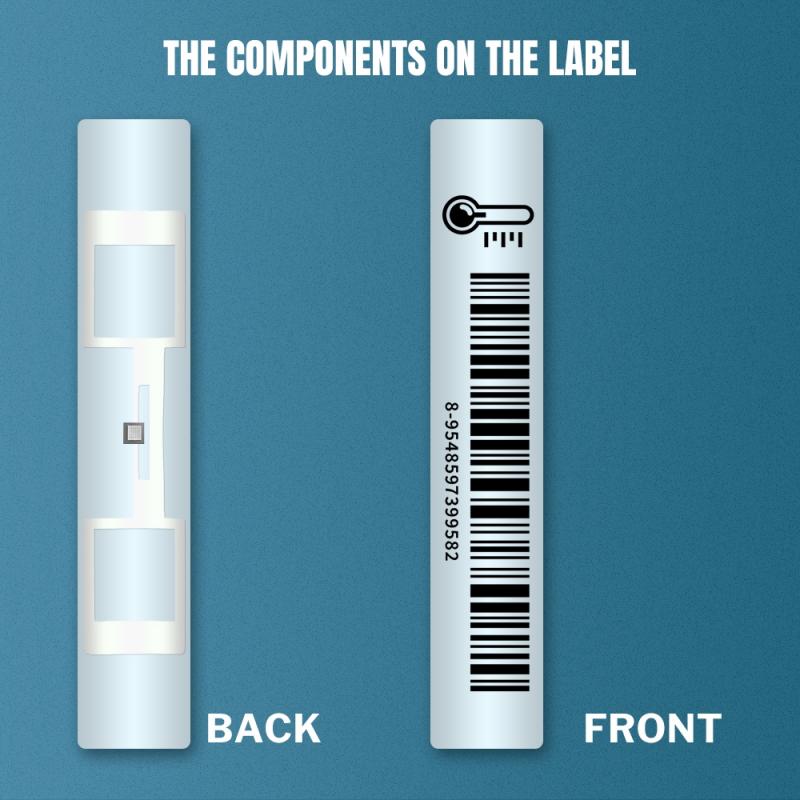

Crystal Code addresses this with an NFC Temperature Label that puts evidence at the edge – right on the box, tote, or pallet. One tap gives frontline teams temperature and identity in seconds. Gate reads and vehicle-mounted devices extend that visibility to lanes and portals, capturing events automatically. Instead of scattered spreadsheets and guesswork, you get a fact pattern that’s simple to read and easy to defend.

• Unverified handoffs that slow FDA, GDP, and HACCP audits

• “Looks fine” decisions that miss short, critical excursions

• Disconnected systems for identity, location, and temperature

• Manual entries that are late, incomplete, or inconsistent

• Write-offs and claims from preventable temperature abuse

By making temperature data immediate and unambiguous, NFC Temperature Label shifts teams from reacting to incidents to preventing them. Operations gains real-time awareness. QA gains clean histories. Finance gains fewer losses. Customers gain confidence.

What Crystal Code Delivers With NFC + RFID

Crystal Code engineers labels for real life – condensation, vibration, extreme temperatures, and all. We combine the ease of NFC with the reach of UHF RFID to create a cold chain temperature monitoring workflow that fits today’s process and scales tomorrow. This balanced architecture is ideal for pharmaceutical cold chain monitoring and food logistics temperature tracking, where unit-level detail and lane-level oversight both matter.

1) Passive And Active Options

Our portfolio includes both passive and active configurations so you can match cost to risk without compromising coverage.

• Passive NFC/RFID labels draw energy from the reader and return temperature plus product identity in a tap or scan. They are ideal for unit-level, high-volume deployments, with typical read ranges from ~0.1 m to 7 m*. Use them where quick verification matters – packing benches, receiving desks, or clinical pick-and-pack.

• Active labels include a built-in battery that logs temperature at set intervals or on demand and stores thousands of records. They support long-distance reads up to 30 m+* and enable real-time or batch uploads. This option is perfect for lane coverage across warehouses, cross-docks, and trailers where you need continuous visibility without manual taps.

With both options in your toolkit, you can apply passive at scale for everyday shipments and reserve active devices for high-risk lanes, long dwell times, or shipments with stringent documentation requirements.

2) Accuracy, Range, And Rugged Design

Cold chains are unforgiving. Our labels are built accordingly. Professional-grade sensors deliver ±0.3°C to ±0.5°C typical accuracy (at 25°C) across a -40°C to +85°C measurement window. That span covers deep-freeze storage, chilled transport, ambient staging, and even high-temperature sterilization steps.

To survive the journey, labels carry IP67/IP68 ingress protection – waterproof, dustproof, and shock-resistant – inside rugged ABS/Epoxy housings. Operating temperature also spans -40°C to +85°C, giving you reliable performance in damp cold rooms, clean environments, and the bouncing reality of vehicle bays. When a label reads, you can trust the number – no drama, no recalibration surprises.

3) Integration And Data Access Made Simple

Technology should work with your infrastructure, not fight it. Crystal Code aligns with EPCglobal UHF Class 1 Gen2 / ISO 18000-63, operating on 860-960 MHz global bands. That means your existing RFID readers, gates, access control points, and vehicle-mounted devices are ready to go. A single read can provide Identity (Who), Location (Where), and Temperature Status (What) in one event, creating clean, unified records.

Data moves to your cloud or local platform to produce visual reports and meet FDA, GDP, and HACCP audit demands. For spot checks, handheld readers work flawlessly on the floor. For continuous operations, fixed portals capture movements and temperatures automatically. The result is a coherent history that stands up to internal review and regulator scrutiny alike.

*Certifications: CE, FCC, RoHS – because reliability includes regulatory trust.

Business Impact And Deployment Playbook

Great technology earns its keep by making problems smaller and decisions faster. When NFC Temperature Label becomes part of your standard workflow, the operational benefits show up quickly. Teams stop hunting for proof and start using it. Investigations shrink from days to minutes. Variance falls because handoffs are documented and transparent. The finance team sees less shrink and fewer claims. Sales has stronger on-time, in-spec performance to showcase.

In pharmaceuticals and biologics, unit-level verification prevents small excursions from becoming big deviations. In food and beverage, pallet-level reads confirm that cold integrity held from dock to store. For 3PLs and retailers, portal reads automate dwell-time tracking and temperature exception alerts. In manufacturing, labels validate process stages, including high-heat sterilization and post-sterilization holds.

Here’s how teams typically roll out Crystal Code solutions without disrupting the day job:

• Map Critical Points. Identify where temperature risk spikes – receiving, staging, cross-dock lanes, long waits, and vehicle transfers.

• Choose Label Strategy. Use passive labels for high-volume verification at close range; apply active labels where you need continuous logging and lane coverage.

• Instrument Reads. Combine handhelds for mobile checks and fixed portals for automatic capture at gates and busy chokepoints.

• Normalize Data. Feed events into your existing platform to generate visual reports that mirror your audit pathways.

• Train For Exceptions. Teach teams how to respond when a read flags an excursion: quarantine, investigate, document, release or dispose – no ambiguity.

• Prove ROI. Track shrink reduction, fewer write-offs, shorter investigations, and faster audits. Let the numbers justify scale-up.

✅ Typical Deployments

• Pharma & Biologics: Serialization plus temperature proof for lane-by-lane traceability.

• Food & Beverage: Pallet reads confirm dock-to-store integrity and reduce recalls.

• 3PLs & Retailers: Gate events drive dwell-time and temperature exception alerts.

• Manufacturing: Validation through high-heat steps and post-sterilization holds.

Crystal Code supports the full journey: assessment, pilot design, reader and label selection, workflow integration, and operator training. We help you pick the right mix – where passive delivers the best cost profile, where active closes data gaps, and how to present history that auditors accept immediately.

Call To Action

Close the blind spots in your cold chain with a pilot that pays for itself. Talk to Crystal Code about an NFC Temperature Label rollout tailored to your lanes, product risk, and audit requirements. We’ll map read points, align reporting with FDA/GDP/HACCP, and quantify ROI – so your team can act before a temperature blip becomes a loss.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper