Heat-Resistant Self-Adhesive Labels: Benefits You Should Know

By hqt

Heat-Resistant Self-Adhesive Labels keep vital data readable when heat, chemicals, and abrasion threaten to erase it. In fast-moving plants, labs, and service bays, a label is often the only bridge between a part and its history. When standard stickers fade or curl, barcodes stop scanning, batches lose identity, and compliance questions follow. At Crystal Code, we design and supply labels that stay put and stay legible – through the heat cycle, the wash, and the final audit.

Why Heat-Resistant Self-Adhesive Labels Matter Now

Production has grown hotter and more automated. Conveyor lanes run beside ovens, boards ride through reflow, and tools cycle through high-temperature sterilization. In these settings, ordinary labels fail early; every failure invites rework, scrap, and unplanned downtime. Our Heat-Resistant Self-Adhesive Labels are engineered for these realities. They safeguard data from the first scan at kitting to the last scan at shipping, keeping systems synchronized and operators confident.

Crystal Code builds durability into every layer. The face stock uses specialized, temperature-resistant materials chosen for stability under sustained heat. Heat-resistant coatings preserve print contrast when exposed to heat, chemicals, and abrasives, so the code you print is the code you scan after processing. High-performance adhesives maintain grip through thermal stress without tearing, bubbling, or leaving residue that complicates inspections. The result is a label that performs where high-temperature manufacturing labels are not optional but essential.

✅ Where ordinary labels go wrong

• Heat spike distortion: Standard stocks soften, curl, or blister, turning clean barcodes into guesswork.

• Chemical splash: In finishing lines and maintenance bays, ink and coatings break down, causing unreadable marks.

• Surface mismatch: Smooth metals, textured plastics, and glass each challenge adhesion; many labels lift at the edges.

• Handling abrasion: Rough handling rubs off print and corners, creating scan failures at the worst time – final inspection.

Built for the Heat: Construction That Lasts

The value of Heat-Resistant Self-Adhesive Labels is simple: they continue to identify parts accurately after exposure to punishing conditions. That reliability depends on the trio of face stock, coating, and adhesive working as a system.

Our labels apply cleanly and stay put on metal, plastic, and glass. They resist edge-lift as parts warm and cool, avoiding the “peel and replace” spiral that stalls takt time. Coatings keep text and codes sharp against glare and grime, supporting quick scans on moving lines. For teams focused on lean operations, that stability removes a small but costly source of friction.

✅ Adhesion that holds under thermal cycling

Thermal cycling stresses adhesives. Surfaces expand and contract; oils, dust, and condensate complicate the bond. Crystal Code specifies high-performance adhesives that wet out quickly, bite into varied textures, and maintain contact through heat, movement, and vibration. The practical effect is fewer re-labels, fewer operator workarounds, and more consistent data in your MES or ERP.

✅ Legibility that resists fading and abrasion

Print quality is more than a cosmetic concern. Low contrast or missing modules turn a valid barcode into a defect. Our heat-resistant coatings protect printed data against prolonged heat and routine chemical exposure, so high-temperature barcode labels remain scannable in real workflows – not just in a lab test.

Proven Across Industries and Workflows

Complex operations demand dependable identification. You will find Heat-Resistant Self-Adhesive Labels wherever traceability intersects with heat and handling:

• Electronics & circuit boards: Survive soldering and reflow, keeping barcodes crisp for inline quality checks and downstream assembly.

• Automotive & engine parts: Stay readable on hot housings and under-hood components that face oils, vibration, and frequent touch.

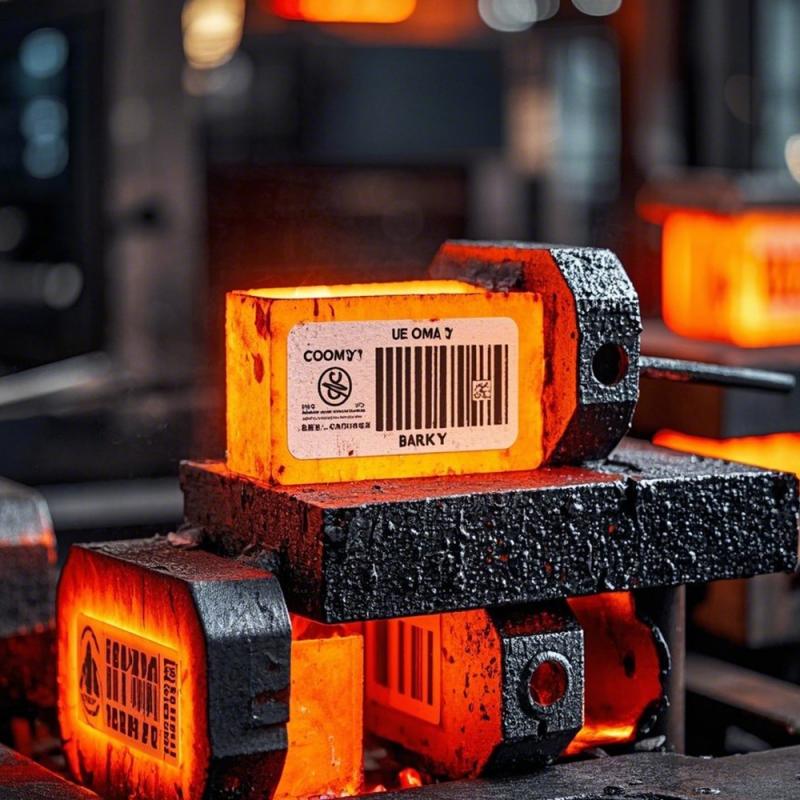

• Steel & high-temperature manufacturing: Maintain adhesion near ovens, heat treatment, and finishing processes.

• Aerospace: Support rigorous identification where reliability and traceability are non-negotiable.

• Medical equipment & sterilization: Endure high-temperature sterilization without peeling, flaking, or degraded print.

• Packaging lines: Enable clear SKU, lot, and regulatory markings on varied substrates at speed.

These use cases share one requirement: labels must outlast the process. With Crystal Code, teams cut relabeling, reduce scrap, and close the traceability gaps that lead to returns or audit findings. For buyers comparing options, our industrial heatproof adhesive labels remove a quiet bottleneck – mislabeling – and let throughput and quality targets coexist.

✅ Materials and print clarity, balanced

Durability and clarity should not compete. Our constructions balance toughness with the crisp edges scanners prefer. Readers lock onto codes fast, and auditors find information where they expect it – still attached, still legible. That little improvement scales across shifts and sites, turning fewer rescans into noticeable gains in rhythm and reliability.

Beyond the Label: Service That Fits Your Operation

Selecting a durable label is a strong first step. Implementation speed, packaging design, and delivery reliability determine the value you feel on the floor.

Packaging Design and Innovation. Our design team pairs your technical needs with market-aware packaging that looks professional and works in harsh settings. We prioritize clear information hierarchy, proper label sizing, and substrate matching so critical data stands out and stays readable.

Efficient Production Capacity. Crystal Code operates sophisticated equipment and agile scheduling to respond quickly to changing volumes. Whether you plan a short qualification run or a rapid scale-up, we coordinate timing to support launches and maintenance windows and to keep inventory lean.

Global Logistics and Distribution. We tailor logistics modes and routes to your priorities – speed, cost, or sustainability – so labels arrive when and where you need them. Flexible routing helps reduce logistics costs while protecting production continuity across sites and regions.

✅ What you can expect from Crystal Code

• Durable, high-temperature-resistant labels that retain readability and adhesion in harsh environments.

• Fade-resistant coatings designed to withstand heat, chemicals, and abrasives over time.

• Strong adhesion to metal, plastic, glass, and other industrial surfaces.

• Proven fit for electronics, automotive, aerospace, medical equipment, steel manufacturing, and high-temperature sterilization processes.

Call to Action – Put Reliability to Work Today

If relabeling, rescans, and traceability gaps are slowing your line, it is time to upgrade. Talk to Crystal Code about Heat-Resistant Self-Adhesive Labels. Request samples, ask for a tailored material recommendation, or get a fast quote. We will match face stocks, coatings, and adhesives to your exact process – and deliver with the flexibility your operation demands.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper