Electronics Temperature Sticker Label: Reliable for Devices

By peter, ren

What is a Temperature Sticker Label of Electronics?

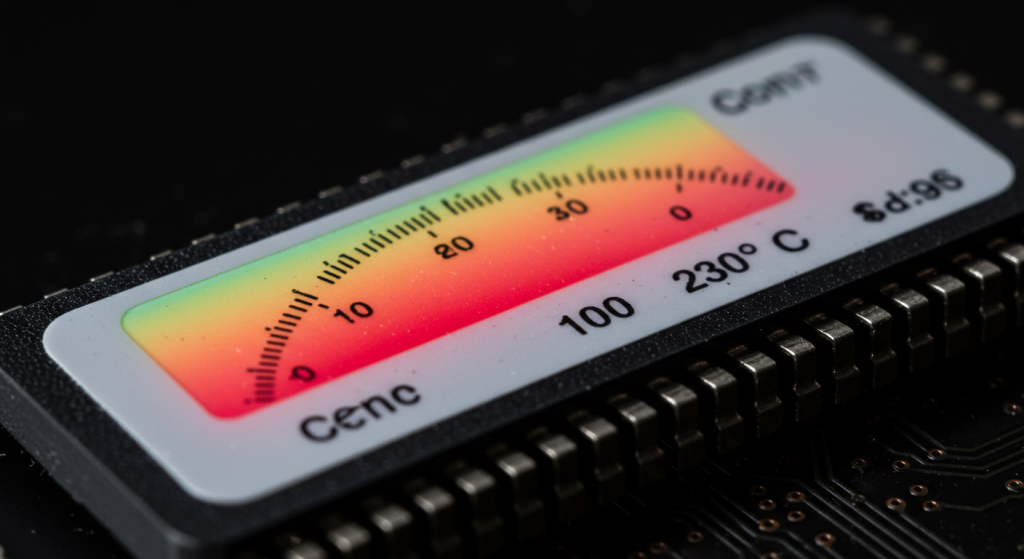

- An electronics temperature sticker label is a temperature-sensitive adhesive label used to regulate the temperature of electronic equipment or parts. These stickers can change color or use a visible indicator once in a particular temperature. Others are reversible (they reverse on cooling), but others are irreversible and permanently record thermal exposure.

- These labels are often thermochromic in nature, meaning that they give visual cues about the temperature level without the use of complicated electronic sensors or expensive equipment. They are small, simple to install, and perfect for monitoring the circuit boards, batteries, and transformers, among other heat-reliant components.

Single-Level Encapsulated Indicator Labels: Perfect Fit

Single Level Encapsulated Indicator Labels have a large temperature range of 50 °C to 200 °C (122degF to 392degF). This is why they are suited to be used as an electronics temperature sticker label, which will allow the reliable monitoring of temperature in different industrial settings. Key Features and Benefits:

- Air-Tight Temperature Gauge

These labels give a permanent, unaccommodating display upon being subjected to a temperature level that is above their specified level. This is a non-tampering feature that guarantees reliable evidence of exposure to temperatures to control quality and guarantee a warranty.

- Wide Industry Usage

They are widely applied in the pharmaceutical industry, electronics, aerospace, the automobile industry, and in food manufacturing. They are also versatile and thus would be suitable when it comes to tracking the transportation and distribution activities in the transportation sector, whereby the accurate temperature of the material is of the essence.

- Several Critical Applications

1. Checking of thermal disinfection temperature.

2. Checking the temperature of the solder in electronic manufacturing.

3. Monitoring the temperatures of the engine components used during warranty claims.

4. Assure temperature integrity in machine maintenance procedures.

5. Alerting the users when the environmental temperatures surpass safe levels.

- Environmental Protection Measures

In an oil-prone, moisture-prone, or harsh liquid environment, it is a good idea to cover the labels with one or multiple layers of clear epoxy. This covers the sticker and guarantees that it sticks to clean and dry surfaces to avoid any damage or misreadings.

- Storage and Application Guidelines

These indicators must be kept under refrigeration conditions, but not in deep freeze conditions, so as to preserve the accuracy. Labeling surfaces need to be dry and free of any dirt to ensure good adherence of the label and accurate temperature measurements.

- Various Industrial Reliability

The electronics temperature label offered by Single Level Encapsulated Indicator Labels is relied on in such vital operations as transportation, assurance of disinfection operations, soldering, engine part identification, and preventative machine procedures.

- Regulatory Conformance and Quality Assurance

These labels contribute to the adherence to the high level of regulation, providing accurate and tamper-resistant temperature measurements. Their operation makes manufacturers and quality controllers not compromise on the product safety and regulatory provisions.

Major Uses of Electronics Temperature Sticker Labels

These labels are versatile, so they can be used in various industries:

- Electronics Manufacturing

Components should be kept within a safe temperature in the course of assembly, soldering, and testing. Temperature indicator labels provide faster, visual confirmation that processes remain in safe temperatures, which minimizes the chances of thermal damage.

- Circuit Board Monitoring

These labels assist in the monitoring of heat generation in devices that are active, and thus, components that overheat are seen early enough and thus prevent failure.

- Consumer Electronics Protection

Smartphones, laptops, and other devices can be monitored with stickers to check battery and interior temperature to avoid the risk of overheating and catching fire.

- Electronics in Aerospace and Automotive

The temperature of critical systems in airplanes and automobiles must be kept at stringent levels. These labels contribute to the safety and regulation.

- Medical Devices

Medical equipment has sensitive electronics that require temperature monitoring to maintain the performance and safety of the patients.

Key to Selecting the Right Temperature Sticker Label for Your Electronics

In choosing a temperature sticker label, look at:

- Temperature Range Required: Adjust the temperature threshold of the sticker to the highest safe temperature of your component.

- Reversible Vs Irreversible: Determine whether you require continuous monitoring or permanent breach records that are permanent.

- Adhesive Type: Make certain that it is compatible with the device (e.g., metal, plastic).

- Environmental Resistance: Harsh environments demand waterproof and chemical-resistant labels.

- Size and Shape: Select stickers that are not too big to cover up the components.

Installation and Good Practices

To ensure the greatest accuracy and adhesion:

- Wipe the surface with a towel to clean it up to eliminate dust, oils, and water.

- Top on at room temperature to be well-adhesive.

- Stickers should be placed on smooth and open surfaces near heat-related parts.

- Do not touch the surface of the labels to avoid contamination.

- To maintain logs, one should note any color changes frequently and record them as maintenance logs.

Compliance and Quality Assurance

- Compliance with industry standards is important to electronics manufacturers and their users. A lot of temperature sticker labels include:

- Accurate and reliable as an ISO-certified.

- RoHS, which means that no toxic materials are used.

- Applied in medical devices that are used in the FDA and those in the aerospace industry that dictate high safety measures.

Why Should You Use CC Sticker on Your Electronics Temperature Sticker Labels?

At CC Sticker, we deal with electronics temperature indicator labels that are high-quality and durable. Our products feature:

- Thermochromic materials that state-of-the-art temperature measurements.

- Powerful adhesives that were chemical-resistant and applied to circuit boards and other electronics.

- Adjustable temperature levels to suit your preferences.

- Quick, dependable worldwide logistics with on-time delivery.

- Technical advice to get the correct label and make the best use of it.

Conclusion

To prevent overheating of your electronic devices, it is necessary to protect them. Using the electronics temperature sticker label, you will have a fast, convenient device that will be able to give instant visual warning signs and guarantee compliance and long-term safety. Visit Crystal Code and discover our extensive selection of customizable thermal stickers and start smarter temperature management today!

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper