Best Matte Vinyl Sticker Paper Tested for Print Quality

By hqt

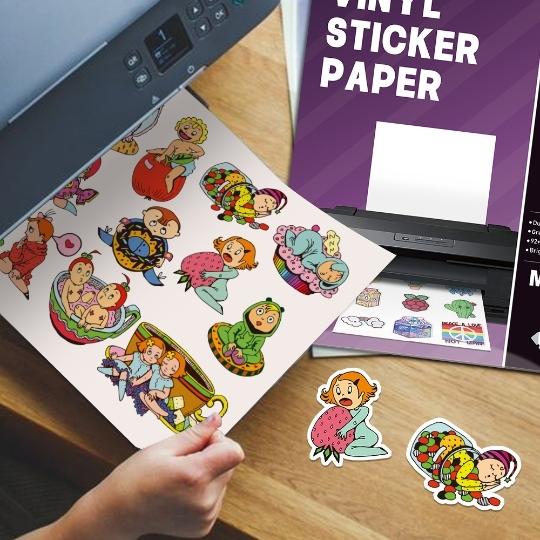

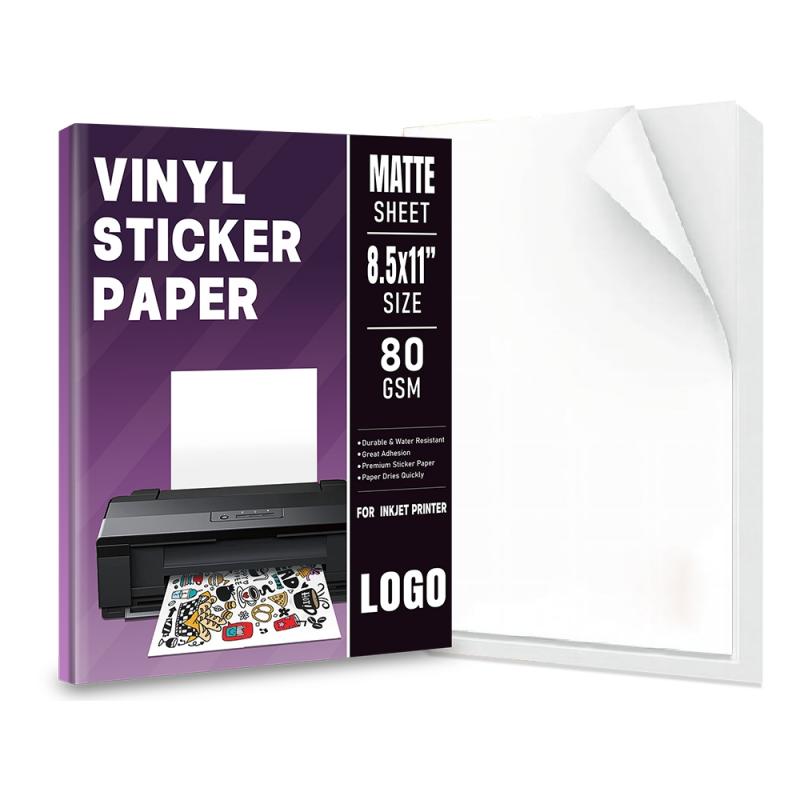

The Best Matte Vinyl Sticker Paper made by Crystal Code is more than a plain sheet; it is the base for clear, durable and professional stickers. It has a smooth matte surface that works with most home and office printers. Colors look rich, lines stay sharp, and the finish feels soft, not glossy. You can use it for product labels, crafts, planners or branding. But what really makes it stand out is how it performs under pressure. How does it handle water, sunlight and daily use? And what do our print quality tests actually show? Let’s take a closer look.

Why Print Quality Is a Big Deal for Stickers

From the outside, a sticker looks simple. But behind that small piece of material is a mix of coating technology, printer settings, ink behavior, and daily use. If any of those fail, the whole sticker fails. In our talks with brands, studios, and small businesses, we hear the same pain points again and again:

✅ Ink spreads on the surface and text loses its sharp edge

✅ Colors look bright on the screen but dull on the sheet

✅ Corners curl up after a few days on the product

✅ A splash of water ruins the design

Crystal Code developed our Best Matte Vinyl Sticker Paper exactly for these situations. The surface has a velvety matte texture with a dedicated inkjet coating. That coating is made to pull ink into a stable layer instead of letting it wander. The result is crisp outlines and high resolution, even when you print tiny text, fine barcodes, or detailed logos.

We also understand that not everyone has a perfect print room. Maybe you share one printer at home and another at the office. Maybe your team uses different models across locations. Our matte vinyl sticker paper is designed to be compatible with most standard inkjet printers and can also work with many laser printers. This gives you flexibility and keeps your workflow simple when multiple people are printing the same design.

Consistent print quality does more than make a sticker look nice. It keeps your brand image steady. Whether you are labeling handmade coffee, skincare sets, candles, electronics accessories, or sending out mailers with fun decals, the material underneath your art should support your message, not weaken it.

How We Test Our Best Matte Vinyl Sticker Paper

If we call a product Best Matte Vinyl Sticker Paper Tested for Print Quality, those words have to mean something. At Crystal Code, that “something” is a structured testing process we apply to every production batch.

We start with color checks. Our team prints patches of strong red, blue, and black, along with skin tones and gentle gradients. We look for banding, random lines, uneven saturation, and any change in tone after drying. A good matte surface should show rich, smooth color without shine, so your labels are easy to read under store lights or daylight.

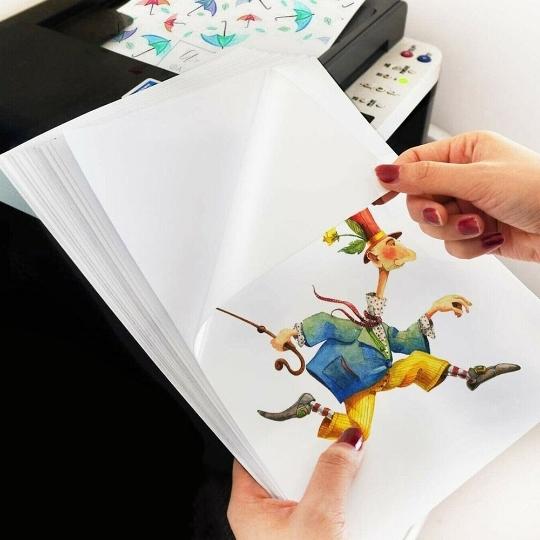

Drying time is another key part of our tests. Slow-drying coatings lead to smudges, especially when you stack sheets or cut right after printing. Our coating formula helps ink set quickly on the surface. In practice, that means you can print, trim, and apply in a short time frame instead of leaving sheets out overnight.

We also bring the stickers into “real life.” That means bending the material, sticking and peeling it, and exposing it to water. Our vinyl construction is waterproof and water-resistant, and when you pair it with a clear laminate or UV sealer spray, you get extra protection for outdoor or heavy-use cases.

Some of the main performance points we track include:

• Ink Adhesion: Ink bonds tightly to the matte coating and does not rub off easily

• Detail Clarity: Fine lines and small fonts stay legible and clean

• Color Stability: Shades remain vivid after drying and over time

• Water Resistance: Prints resist smearing when they meet humidity or splashes

• Adhesive Hold: Stickers grip well on clean, smooth surfaces without sudden lifting

By checking these areas batch after batch, we help ensure that the Best Matte Vinyl Sticker Paper you buy this season performs just like the one you reorder next season. For businesses that rely on repeat packaging or long-running product lines, this kind of stability is not optional; it is essential.

What Makes Crystal Code‘s Sticker Paper Different

As a manufacturer, we do not only see the final sheet. We work with each layer: the printable face, the adhesive, and the backing paper. Our matte vinyl surface is built with a special inkjet receptive coating. That strong ink receptivity is what gives you clean edges and bold color instead of fuzzy outlines and pale prints.

The material is easy to cut and easy to peel. Whether you use scissors, a craft knife, or a cutting machine, the sheet is made to move smoothly through the process. We supply popular sizes such as US Letter 8.5″ x 11″ and A4 210 mm x 297 mm. These sizes fit standard printer trays, so you can load and print without dealing with custom settings.

The backing paper is chosen to balance stiffness and flexibility. It needs to be stable enough for the printer rollers, but still simple to crack or bend when you want to release the sticker. This helps reduce misfeeds and wasted sheets.

Our Best Matte Vinyl Sticker Paper is flexible enough for many day-to-day and business projects, including:

✅ Branded product labels on jars, bottles, boxes and pouches

✅ Custom decals for laptops, tablets and mobile phones

✅ Planner, journal and scrapbook stickers for DIY and craft lovers

✅ Car window and bumper designs when paired with clear lamination

✅ Wall quotes, logo stickers and small indoor signs for décor

Because these stickers face constant handling and changing environments, durability is key. The waterproof vinyl face and strong adhesive help your stickers stay firmly in place on clean, smooth surfaces. For outdoor exposure, or items that face frequent handling, a clear laminate film or UV spray can be added as a protective top coat. This extra shield helps minimize scratches and fading from sunlight.

We also treat safety and compliance seriously. Our materials can be produced to meet standards such as SGS, RoHS, and ISO requirements. For many customers in food, cosmetic, or children’s goods, this is more than a selling point; it is part of their legal and brand promise.

At Crystal Code, we like to think of ourselves as the quiet partner behind your visible brand. You design the logo, choose the palette, and tell the story. Our job is to provide the Best Matte Vinyl Sticker Paper so those choices show up clearly on every surface you stick them to.

If you are ready to upgrade from ordinary sheets to Best Matte Vinyl Sticker Paper Tested for Print Quality, our team is here to support you. Contact Crystal Code for samples, technical advice, or bulk pricing. Let us help you turn every print file into a durable, professional sticker that reflects the quality of your brand.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper