Why Regular Labels Fail Without Heat Resistant Sticker

By hqt

Heat Resistant Sticker is the invisible line between readable, compliant IDs and labels that curl, fade, or fall off when temperatures spike. At Crystal Code, we support plants that run hot – industrial machinery, engines, electronics, aerospace assembly, welding bays, and medical sterilization. Time after time, we see the same pattern: conventional paper or film labels can’t endure peak heat, chemical splash, or abrasive handling. The costs are real – lost traceability, safety risk, and unscheduled downtime. Here’s a clear, field-tested path to stop failure and stabilize identification.

What Really Fails – And Why It Costs You

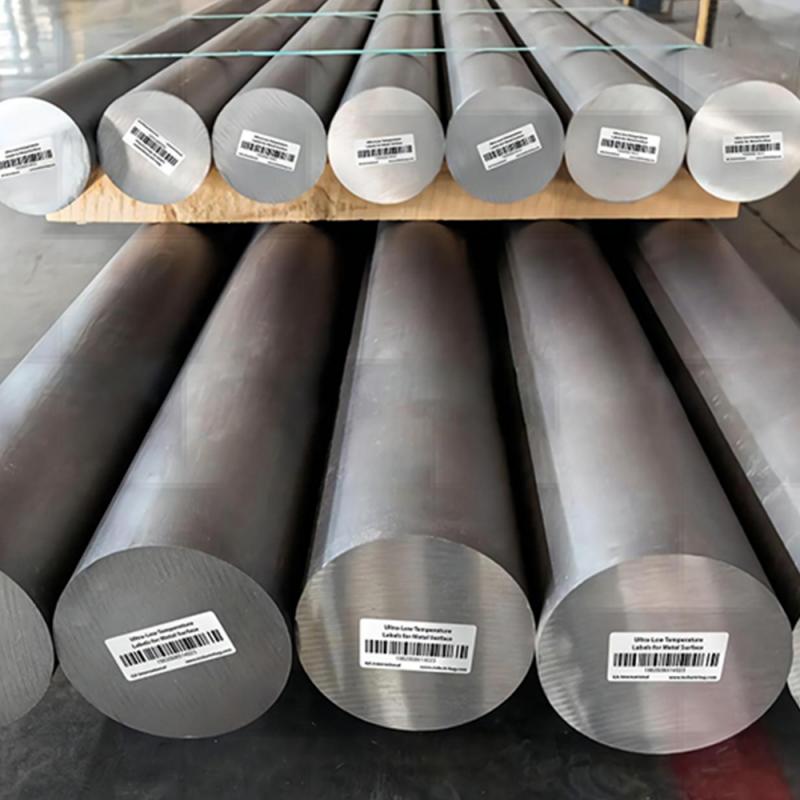

In high-temperature workflows, labels face simultaneous stress: thermal load, chemical exposure, vibration, and challenging surfaces such as polished metals or coated plastics. When a regular label meets this mix, adhesives soften and migrate, films distort, and inks smudge. Operators start replacing labels mid-shift, supervisors chase compliance gaps, and auditors flag unreadable codes. This is not cosmetic – it affects throughput and safety.

At Crystal Code, we design Heat Resistant Sticker constructions to preserve both adhesion and legibility under heat. Our approach centers on high-temperature synthetic films – polyimide and PET – paired with a heat-resistant, chemical-resistant face coating and a high-performance heat-resistant adhesive. Each element is tuned to protect text and barcodes through thermal cycles and chemical contact.

✅ Typical Failure Modes In Heat

- Adhesive Breakdown: Standard glues soften or carbonize; labels shift or detach.

- Ink Instability: Non-resistant inks smudge or fade, making scans unreliable.

- Film Deformation: Conventional films shrink or warp, distorting printed data.

- Surface Mismatch: Smooth metals, coated plastics, glass, and ceramics demand specialized bonding chemistry.

These failure modes explain why “good enough” labels don’t last. Heat Resistant Sticker technology addresses them head-on, helping teams keep IDs readable from first article to final inspection. For sectors that rely on industrial heat resistant labels, that reliability is mission-critical.

Why Crystal Code‘s Heat Resistant Sticker Works

Our product philosophy is straightforward: match the right substrate to the right adhesive and face coating for high temperature labeling across demanding surfaces – metal, plastic, glass, ceramics, and engine components. The outcome is a label that stays put and stays readable, even when processes push toward the limit.

- Materials And Coatings That Last

We specify high-temperature synthetic film, polyimide, or PET depending on your process window. Polyimide thrives near soldering operations and sensitive electronics; PET brings robust durability for engine housings and industrial enclosures. All options are engineered to withstand up to 300°C (572°F) without peeling or degrading, so data remains intact through heat cycles.

A dedicated heat-resistant and chemical-resistant face coating protects print against fading and smudging. The coating also stands up to common process chemicals, supporting longer service life in aerospace, welding equipment, laboratory instruments, and sterilization lines. Because our coating offers strong ink receptivity, text and barcodes print crisp and high-contrast on standard inkjet printer workflows – exactly what fast inspections and automated scans require.

- Adhesion Tailored To Tough Surfaces

Thermal performance means little if the label can’t bond. Our high-performance heat-resistant adhesive is formulated to anchor to metal, plastic, glass, and ceramics, resisting edge lift and adhesive flow. It maintains grip through cycles of heat, cool, and vibration, minimizing residue while maximizing durability. The result is a clean application that survives real production, not just a lab test.

In practice, these construction choices translate to measurable wins on the floor:

- Withstands up to 300°C (572°F) while preserving adhesion and legibility

- Waterproof, good adhesive, easy cut, easy peel for quick changeovers

- Bright coloured options for visibility and safety marking

- Environment-friendly approach aligned with SGS / ROHS / ISO certifications

- Customizable sizes to fit tags, trays, panels, or component geometries

Those features turn labeling from a maintenance headache into a stable control point for quality, traceability, and safety.

Beyond specs, deployment matters. We tailor Heat Resistant Sticker to your environment so the label performs across stations – not just at the easiest step. That’s how lines avoid rework, and audits move faster.

A Practical Path To Switching – From Audit To Scale

Transitioning from regular labels to Heat Resistant Sticker is straightforward when you tackle it in stages. Our team at Crystal Code supports you from assessment through rollout, matching materials and adhesives to your exact conditions.

1) Map The Heat And Chemistry

Start with data: peak temperatures, dwell times, and contact chemicals. Note your substrates – metal, plastic, glass, ceramics – and record any coatings, surface roughness, and curvature. This map guides material choices and adhesive selection, and it sets realistic expectations for cycle testing.

2) Select The Right Build

Based on your map, we recommend polyimide or PET with a heat-resistant, chemical-resistant face coating and a high-temperature adhesive tuned to your surfaces. Need quick visual cues or compliance color codes? Choose bright coloured finishes. Want faster changeovers? Use formats that are easy cut and easy peel to reduce handling time.

3) Validate Print And Application

Print with your current inkjet printer and check barcode contrast. Our coating’s strong ink receptivity helps ensure crisp edges and consistent scanning. Apply to clean, dry surfaces with the recommended pressure. If your process pushes limits, run cycle tests up to 300°C (572°F) to confirm performance under load.

4) Standardize And Scale

Lock down custom sizes for each station and document quick inspection points – edge lift, smear, and scan quality. Standardization streamlines training and keeps quality checks simple. Once the build is frozen, roll it across lines and sites with confidence.

Where will you see the biggest gains? In the same places labels fail most often:

- Electronics & Circuit Boards: Survives reflow-adjacent heat; barcodes stay scannable.

- Automotive & Engines: Bonds to housings, covers, and engine components without lifting.

- Aerospace: Reliable IDs on components that undergo thermal cycling.

- Industrial Manufacturing: Resists heat near presses, ovens, and weld cells.

- Medical & Sterilization: Handles high-temperature cleaning and autoclave-like steps.

By stabilizing IDs in these zones, you reduce relabeling, protect traceability, and prevent downtime triggered by unreadable codes. The combined effect is smoother audits, fewer line stops, and better product confidence.

At Crystal Code, our mission is simple: keep your identification accurate and in place – even when the heat is on. If your current labels peel, fade, or fail near hot zones, it’s time to upgrade to Heat Resistant Sticker and remove labeling from your list of production risks.

Closing Words

Ready to harden your labeling where it matters most? Talk to Crystal Code about a tailored Heat Resistant Sticker configuration for your line. Request samples, get materials guidance, and secure a fast quote – so your most demanding stations stay readable, compliant, and on schedule.

- Agodeo inkjet vinyl sticker paper

- AIVA printable vinyl sticker paper

- best inkjet vinyl sticker paper for outdoor use

- cheap printable vinyl sticker paper for outdoor use

- cold chain temperature indicator

- color-change temperature sticker

- Cricut vinyl sticker paper inkjet

- custom vinyl sticker printing

- DIY sticker paper sheets

- durable waterproof sticker paper for inkjet printers

- electronics temperature sticker label

- glossy inkjet vinyl sticker paper

- hot equipment warning sticker

- industrial temperature indicator label

- inkjet sticker paper for Cricut

- matte inkjet sticker paper

- medical temperature indicator sticker

- multi-point irreversible temperature sticker

- Neato vinyl sticker paper

- one-time temperature indicator label

- orajat 1917 printable vinyl

- peak temperature measurement label

- printable vinyl for car decals

- printable vinyl for laptop stickers

- printable vinyl for scrapbooking

- professional quality inkjet vinyl sheets

- reversible temperature monitor label

- self-adhesive printable vinyl

- shipping temperature indicator label

- Tear-resistant sticker paper

- temperature indicator for food safety

- temperature monitoring sticker for transport

- vinyl sticker paper for labels

- waterproof printable vinyl paper

- where to buy inkjet vinyl sticker paper